Sesame Tahini Production Line 500 kg/h

Brand:GELGOOG MACHINERY

Certification: CE

Pay Method: WEST UNION L/C T/T CASH

Warranty Time: 12 Months

Loading Port: Shanghai/Qingdao

Country Of Origin: China

Details:

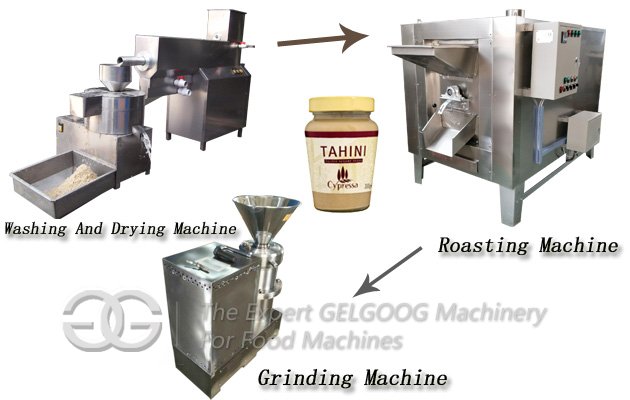

Main equipment for sesame tahini production line are roaster machine, peeling machine, picking belt, lifting machine, coarse grinding machine, mixing tank, pump, mixer, homogenizer, fine grinding machine, vacuum tank, cooling machine, filling machine, etc. Characterized by a flow operation, high mechanization degree, good reliability, full enclosed production, no pollution, is the advanced equipment for production stable sesame paste.

Introduction of Sesame Tahini Making Machines

(1) Roaster machine: Used for baking sesame seeds.

(2) Cooling belt: Use the fan out of heat, cooling the sesame seeds after baking.

(3) Peeling machine: Remove skin of sesame after roasting, during peeling process, kernel and skin automatically separating, ensure the quality of peeled sesame.

(4) Picking belt: Pick out unqualified sesame and some food residue.

(5) Coarse grinding machine: The first grinding sesame seeds into paste.

(6) Fine tahini grinding machine: Further grinding the sesame paste after coarse grinding,fineness further improved.

(7) Cooling machine: Cool the temperature of sesame tahini after grinding.

(8) Degassing tank: Before filling, degassing sesame paste.

(9) Filling: filling and packaging.

Colloid mill products is for fine processing of mechanical fluid materials. It combines homogeneous machine, ball mill, three rollers machine, shearing machine, mixer, etc a variety of mechanical performance. Colloid mill is the basic working principle of shearing, grinding and high-speed mixing effect.

Two grinding on the tooth surface of relative movement, the base of a high-speed rotation, another still, make the material through the tooth face between great shearing force and friction force. At the same time, in the high frequency vibration, high speed spiral complex force under the action of making materials such as effective dispersion, floating, crushing, homogeneous.

Advantages:

This machine is widely applied in the industrial productions of food (Peanut butter, sesame jam, soy milk, dairy products, soft drinks and etc.), medicine (syrups, nutrition liquid, Chinese herb extracts, poultice and etc.), daily chemical products (tooth paste, cosmetic, washing agent and etc.), chemical industry products (pigment, dye, dope, lubricant, petroleum activator and etc.) and the flotation and emulsification of the explosives.

1.This machine is a new type of equipment for the wet type super-micro processing, suitable for the homogenization, emulsification and communicating of the emulsions.

2.This machine has an advanced design, it can adjust rotate speed of millstones according to different demand of different materials, and users can exchange optionally the blast motor for different materials and working condition.

3.This machine has ascendant efficiency(communicating of the emulsions, spread around, emulsification, suitable for the homogenization etc.), the granularity processed can reach to 2-60μm, the homogenization reaches to 95%.

Technical Data:

| Name |

Dimension (mm) |

Power (kw) |

Weight (kg) |

| Screw Elevator | 2000*600*2000 | 0.75 | 150 |

| Sesame Cleaning Machine | 2300*500*1350 | 0.75 | 200 |

| Drying Machine | 1000*800*650 | 1.5 | 100 |

| Elevator | 3000*600*3000 | 0.75 | 220 |

| Continuous Roaster | 3500*1400*2600 | 75 | 3000 |

| Pneumatic Conveyor | 1.5 | 250 | |

| Cooling Storage Hopper | 1500*1000*2000 | 1.5 | 250 |

| Combined Grinding Machine | 1000*400*900 | 22 | 270 |

| Storaging Tank | 300L | 150 | |

| Mixing Tank | 300L | 2.2 | 300 |

| Vacuum Degassing Tank | 300L | 2.2 | 300 |

| Paste Pump | 1.5*2 | 100*2 |

Leave message for price:

Small Scale Peanut Butter Manufacturing Plant In India

Peanut butter on the market today is made from a specialized peanut butter manufa

02/01/20Read More

Chilli Processing Machines Sold To India

On October 8th, our chili processing machine will be sold to India . 1 unit of mi

10/10/19Read More

How to Remove Black Gram Bean Skin Easily ?

Black gram beanis a legume grown in India and has many good health benefits. Itca

31/07/18Read More

Four Steps Get the Skins Off of Peanut

If you want to get the skins of peanut ,how do you get the skins off of peanuts?

27/07/18Read More